Numbers and their uses

Chapter 2 - Understanding Numbers

Section 2.2 - Interpreting Numbers

Two times zero is still zero and half of infinity is still

infinity.

If you

want to develop good engineering judgment you

need to understand the profound meaning of this perspective on zero and

infinity. When dealing with very small

numbers, it makes no difference in the greater scheme of things whether

the number is doubled or not. The number will

still be a small number and needs to be interpreted that way.

Similarly

when dealing with large numbers, even if you halve

the number you still are left with a large number. For all numbers in

between you can use relative comparisons , however,

for small and large numbers, one needs to understand that relative

comparisons may not hold true.

You are probably confused as to what defines a really large and small

number. Relative does not have any absolute number interpretation.

Relative comparison only has meaning in relation to what you are comparing

to. You have to use engineering judgment to see what range most

numbers fall within.

For example, a transportation engineer measuring average

traffic flow on a highway will see most speeds fall within 45-65 mph.

The engineer only needs to focus on speeds in that range

and ignore the really small speeds close to zero. The slowest car in one highway may be 30 mph and in

another highway could be 10 mph. This does not mean the first highway has a 300% higher average

speed of slow cars. It means both those speeds are well below the average speed and

cannot be compared to each other. The example next will explain this in more detail.

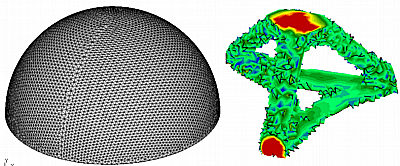

Consider an engineer who is given a half-sphere of material and is

asked to build a stool from it that will be supported at three points.

The engineer needs to find the optimal load path to support a person

sitting on the top of the sphere and supported at three points

equidistant apart at the base. This type of analysis is called

'Topology Optimization' and requires building a virtual model on the

computer and uses equations of calculus and material science to solve a

computationally intensive simulation on a supercomputer.

The picture above on the right is called the 'Optimal load path' .

The way to interpret it is areas in red indicate areas of highest

stress, so need material there. Areas in green are also under stress,

while areas in blue have almost no stress. Actually most of the sphere

is blue, however, all the blue parts of the model were taken out of the

sphere so you could see the internal green and red parts of the model.

Before continuing, it will be useful to understand what

stress means. Stress is an engineering concept and is simply the

load or force divided by the area over which it is applied. Materials

fail when the internal stress from external loads exceeds their allowable

yield stress. Materials like steel have a high yield stress while those

like

rubber have a low yield stress.

Think of this as a pin pricking you. A pin with a sharp point will

be a lot more painful than a pin with a blunt point. The reason is the

same

load is going through a small area, thereby increasing the stress you

feel.

Now suppose the same problem of designing the stool

were given to another engineer. This engineer will

use a different software and methodology to build his virtual model.

In areas where the sphere is taking no load, the results from

both engineer's model should be blue

or the stress should theoretically be close to zero. However one engineer

says the stress in the blue area is 1 MPa, while the other says

it is 2 MPa ( MPa is a measure of force per unit area ). Does this mean the second engineer is producing results

with 50% error ? No , it means both engineer's analysis are outputting

very small

numbers which are close to zero and therefore the SAME number.

Now consider you are looking at load near one of the three support points

at the base. Theoretical results say the stress from load should be

infinity as you have a high load going through an infinitely small

point. Now one engineer says it is 6000 MPa, while

the other engineer's analysis shows 3000 MPa. Again does this mean

the results have 50%

error? No, it means both engineer's analysis

are outputting very large numbers which correlate to the trend of

infinite stress and are therefore the SAME number.

Too many engineers only focus on the absolute numbers when comparing

analysis results. Good engineering judgment involves looking at relative

differences and also seeing how large or small the numbers are when

making comparisons. Another way of thinking of this is in terms of

order of magnitude. Small or very large numbers within the same order

of magnitude are essentially the same number for all practical

purposes. This is not only true in science but all life in general.

It is important to understand the concept of interpreting numbers as

even many engineers with PhD's do not get it. Often those in the

scientific community are too focused on the absolute details and fail to

see the bigger picture around them.

Another problem scientists have is

reporting results with too many significant digits. For example an

atmospheric

scientist

who says the temperature is 97.6756 Farenheit or 22.22323 Celsius is

only confusing you by adding so many significant digits. They may be more

'accurate', however by increasing confusion they defeat the purpose behind

reporting

the number! Only report just enough digits that are truly

significant. So one should report temperature to within 1 whole degree as

few people

can perceive differences of a tenth of a degree.

Of course there are many situations where modeling the absolute

response is of critical importance. It takes good engineering judgment

to know when one needs to look at absolute numbers and when one needs to

only look at relative differences in numbers. You are now in a much

better position to interpret numbers now that you understand

how relative comparisons work for large and small numbers.

Next section ->

Section 2.3 - Risk Assessment